About us

1.Material available for Metal etching

|

Alloy 42

Alloy 48

Beryllium Copper

Brass

Copper

Hastalloy

Hy-mu 80

Inconel

Invar

Kovar

Metglas

Molybdenum

|

Monel

MuMetal

Permalloy 80

Phosphor bronze

Silicon steel

Spring steel

Steel

Stainless Steel (SUS304,SUS301,SUS430 and so on)

|

Julid stocks a wide selection of metals with various tempers and thicknesses. It is likely that we can meet your metal requirements from our stock.

Metal Alloy Temper

Most metal alloys that Julid can use with the metal etching process are available with different tempers. These tempers determine some physical properties of the metal. The physical requirements of your part will dictate the temper of the metal you decide to use.

2 .Metal etching Thickness

Julid can produce your part with chemical etching from sheets of metal ranging in thickness from .000098 inch (0.0025 mm) up to .006 inch (1.5 mm). Metal thickness tolerance often varies with the metal thickness; generally, the thicker the metal, the larger the thickness tolerance associated with it.

Julid stocks a wide selection of metals with various tempers and thicknesses. It is likely that we can meet your metal requirements from our stock.

Julid metallurgists are available to help you select the most appropriate metal for your application.

3. Metal etching Geometry

Overall Part Size

Julid typically produces metal etching parts from metal sheets that measure 8.6 inch (220 mm) by 7.089 inch (180 mm). The overall size of the parts we make can vary from a single part occtal upying an entire sheet to those yielding several thousand pieces per sheet. Depending on the metal required, the largest part we can manufacture is 23.6 inches (600 mm) by 27.56 inches (700 mm). The smallest part that we can make is dependent on the parts geometry and thickness.

Part Configuration

The Julid Process places no limit on the complexity of your metal etching parts configuration as long as the dimensions and tolerances along the plane of the part are within our capability, as explained in the next section.

4.etching process Capabilities

There are limits to the dimensions and tolerances that can be machined along the plane of the metal etching sheet, since etchants used in the photo chemical machining process concurrently etch metals laterally and vertically through the thickness (T) of the sheet.

Because the metal at the surface of a sheet is exposed to etchant longer than the metal at the center of the sheet, the surface of a part etches laterally more than metal at the center. The following planar dimensions are related directly to the thickness of that sheet.

Hole Size/ Slot Width

The smallest hole diameter (D) or slot width that can be produced by the JULID process, as a general rule, is 1.5 times the metal thickness. The minimum practical diameter or slot width that can be machined is .004 inch ( 0.1 mm)when the thickness of material is below 0.05 mm.

Bar Widths

Spacing of metal between the holes and/or slots in a design is not an issue using photochemical machining. However, when a part contains holes and/or slots that are spaced closely together, such as with a fine resolution screen or encoder disc, the width of the metal that remains between them is referred to as the bar width (W).

With metals over .0012 inch (0.03 mm) thick, minimum bar widths must generally be at least 1.5 times the metal thickness. With metals at or under .0012 inch (0.03 mm) thick, the minimum practical bar width that can be machined is .0039 inch (0.1 mm).

Radii

In the photochemical machining process, all corners in a part, whether within or along an outside edge, will have an associated radius. The examples of various part corners and angles illustrate how we can compensate for some radii, and will help you determine whether these compensations are appropriate for your design.

4. Tolerances

Center to Center Tolerances

Center to center accuracy is determined photographically, rather than by the metal etching process. This tolerance is typically considered to be within +/- .0005 inches (.013 mm) over 6 inches (153 mm).

Etched Dimensional Tolerances

It is not possible to establish hard and fast rules regarding etching tolerances since so many factors are involved. Some of the variables that affect accuracy are: type of metal; size of sheet; size of the production run; and the number of critical dimensions per part. Typically, an etched dimensional tolerance of +/- 10% of the metal thickness is considered acceptable by the industry.

Metal etched Parts that are designed with score lines for hand forming, such as RFI and EMI shields, are an exception to this guideline. The dimensional tolerance for hand-formed parts is approximately +/- .010 inch (.254 mm). Dimensional tolerances for parts that are formed with hard tooling after photochemical machining have to be determined on a part specific basis by the fabricator.

Finally, dimensional tolerances for dropout parts are different than for metal etching parts that remain in the sheet. Refer to the section under "Tabs" for more information.

5. Tabs

What are tabs?

In most cases, your metal etching part will be etched from a sheet of metal. Parts are held in sheets by several small tabs which may leave a burr when detached. It is important to note that this burr is unlike a progressive die burr. There are two types of tabs used in the Zhulida Process: External and Recessed.

External Tabs

External tabs will produce a break-off point that will leave a small part of the metal sheet on the part.

.jpg)

.jpg)

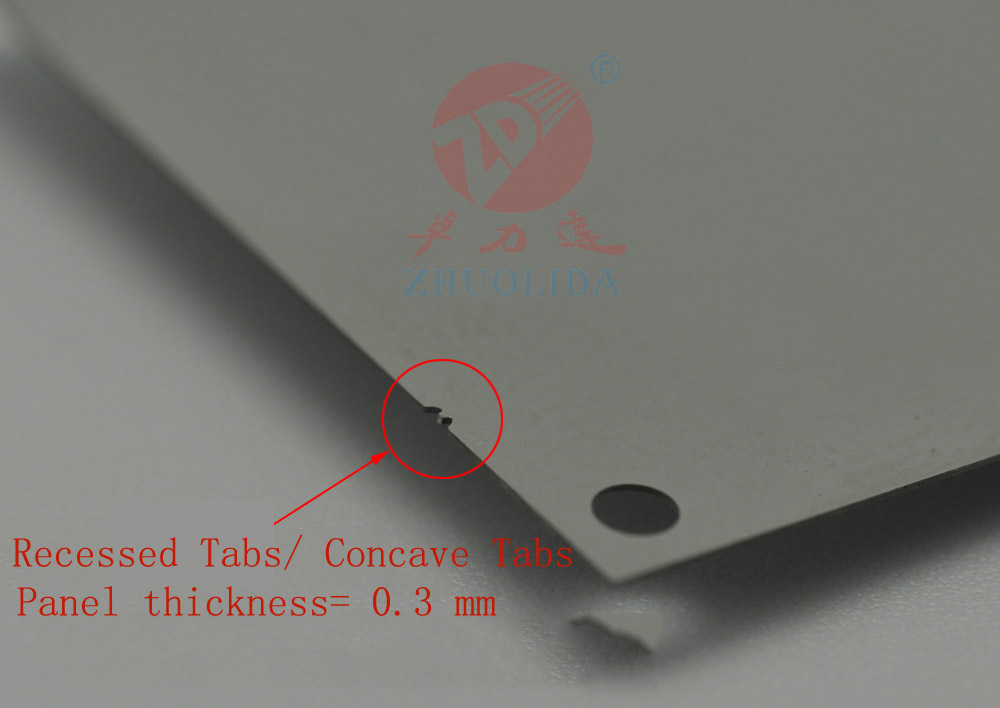

Recessed Tabs

Recessed tabs are similar to external tabs except that the break-off point will be recessed into the part. > Use this option if your part cannot have any areas extend beyond its perimeter. Typical applications that use the recessed tab are parts such as encoder discs and other circular parts, washers, and shields. RF/EMI shields will use recess tabs so that the tab does not affect the fence´´´´s attachment to the PCB.

What are my options if my part cannot have tabs?

We can produce your metal etching part without placing any tabs to hold the part to the sheet. This is referred to a having drop-out parts. The benefit of going with drop-outs is clearly losing tab, but since the parts are less stable (they are no longer tabbed into the sheet) we generally have loser tolerances on drop-outs. Additionally, the etching and stripping processes create a higher yield loss. Parts that make good candidates for drop outs depend on metal thickness (the thicker the better), part design and most importantly tolerances.

6. Data

JULID drafting engineers have experience working with customer drawings ranging from E-size prints to hand drawn sketches to CAD files. You can use the following methods to communicate your drawing to us.

E-mail your CAD file in .dxf, .dwg or .pdf format