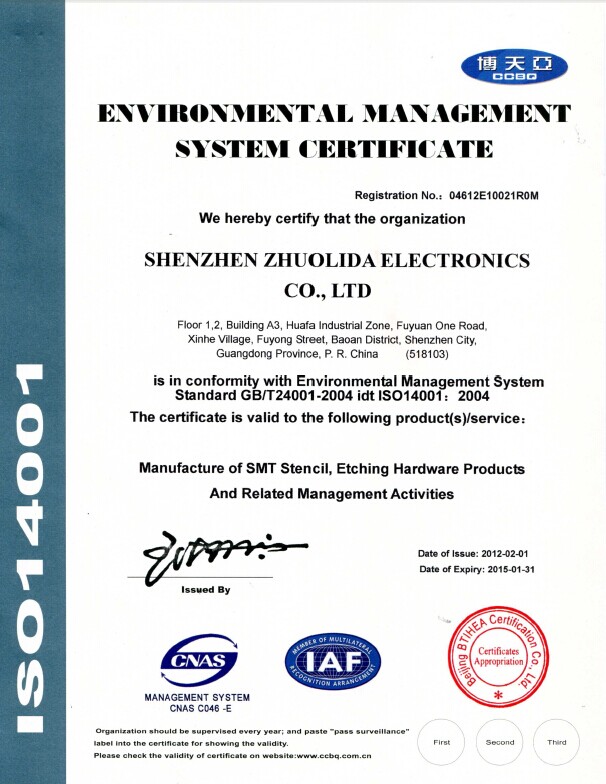

photo etched washer

| Introduction: | OEM is welcome |

| Application: |

Product details

photo etched washer

Low Cost Photo Chemical Etching

Low risk, low cost set-up with No expensive hard tooling means low cost set-up with no significant cost penalty for amending and optimising designs.

High Speed

Samples can be provided quickly while the same technology can produce economical volume quantities, minimising ´critical development paths´ and reduce ´time to market´.

Material diversity Virtually all metals can be etched, including stainless steel and ´corrosion resistant´ advanced engineering alloys. Even metals that are hard or brittle can be etched. Photo Etching is ideal for machining thin metals and foils.

Stress and Burr Free

Photo Etching is a cold chemical process that corrosively removes unwanted material. The process does not induce stress or deformation, unlike presswork where parts are subjected to substantial mechanical forces and stresses. Photo Etched components are burr free while temper and magnetic properties remain unchanged.

Ease of Use Techniques such as half-etched bend lines facilitate complex hand forming of parts, saving the cost of hard tooling. Integrated marking reduces handling and cost. Photo etching is the recommended and in many instances the superior alternative to precision presswork & laser cutting.

Materials

Amorphous Metals, Aluminum, Beryllium Copper, Bi-Metals, Brass, Brazing Foils, Copper, Copper Alloys, Iridium, Maraging steels, Magnesium, Mild Steel, Molybdenum, Mumetal, Nickel, Nickel Alloys, Nickel Iron, Pewter, Phosphorous Bronze, Radiometal, Silver, Spring Steels, Stainless Steels, Tantalium, Tin, Titanium, Titanium alloys, Zinc, Zirconium, Zirconium Alloys

Related Products

Shims: 1. 0.03 mm up to 1 mm 2. compliant with ROHS directive 3. EDM & ODM products[更多]