Product details

Julid is experienced in developing, manufacturing and improving custom RFI and EMI shielding. Shields can be manufactured exactly to your desired specifications. Here we can provide customers with two methods to make emi shielding: 1.stamping shielding; 2. chemical etching shielding

1. Use Stamping to make your shielding

1) It will cost us about 7 working days to make the mold for you, cost for mold is about 250 USD to 350 USD, according to your design.

2) Leadtime for samples will be 10 days, leadtime for mass production wil be 10-15 working days.

3) Material can be brass or stainless steel. Generally, thickness is ranging from 0.1 mm up to 0.3 mm

4) Added processes: We have our own in-house forming department. Welding seams closed-we do laser welding in-house. Soldering open seams shut. Plating, especially to brass and steel parts, plating helps in soldering to boards and protection from oxidation of the base material.

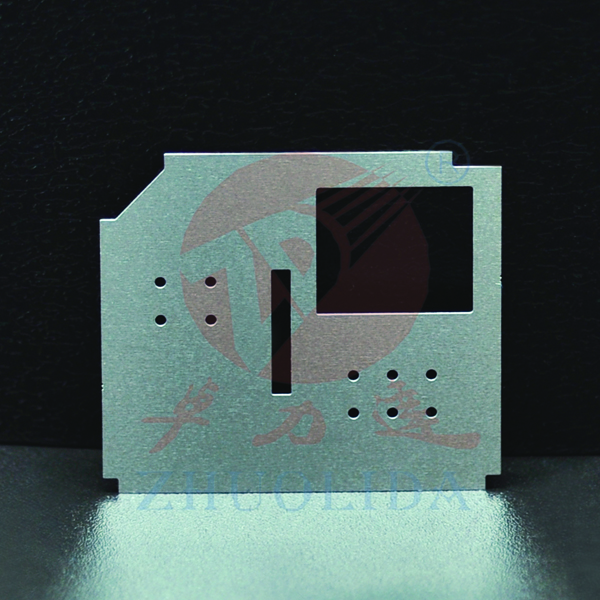

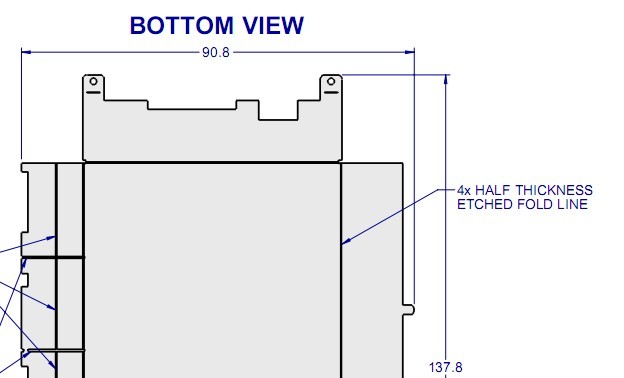

2. Use chemical etching to make your shielding

Shields can be etched as flat pieces with or without etched bend lines on the bottom side of the shielding to ease forming at your facility or we can form at our in-house forming department. Part numbers, logos or other identification can be included on your shields as well, further developing the shielding to your requirements.

One piece emi shielding, shielding with peel away tops or two piece shields consisting of a “fence and cover” combination are typical designs for shielding. We are willing to work with you as you develop your custom application.

1) By using chemical etching method, we don''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''t need to make any mold, but will charge you only 100- 150 USD for the starting fee ( for 10 pcs samples)

2) Leadtime for samples is 3-5 working days, for mass production is 7 working days

3) Material can be brass or stainless steel. Generally, thickness is ranging from 0.1 mm up to 0.3 mm

4) Added processes: We have our own in-house forming department. Welding seams closed-we do laser welding in-house. Soldering open seams shut. Plating, especially to brass and steel parts, plating helps in soldering to boards and protection from oxidation of the base material.

For more technique information, please Send E-mail to us:

Contact: Selina Liang (Export manager)

E-mail: yw1@zldsmt.com

Tel: +86-0755-61501695

Skype: Julid2012

Related Products