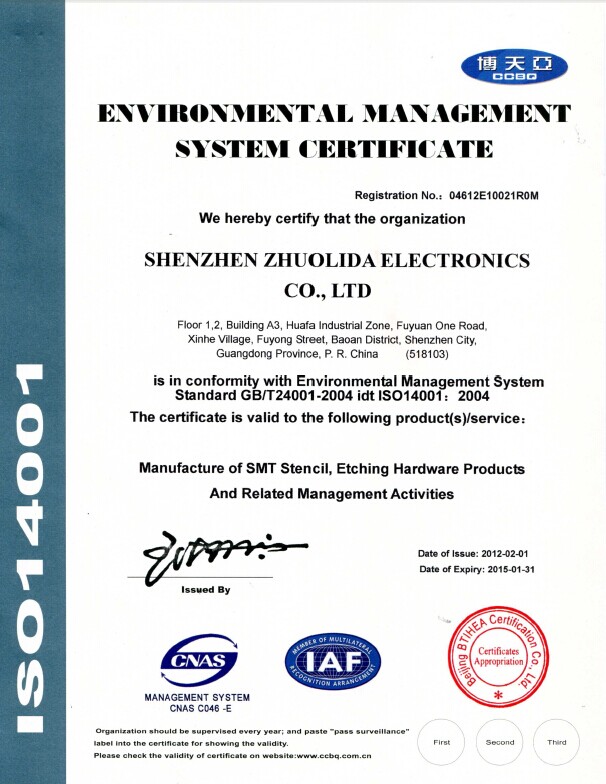

stainless steel shim

| Introduction: | Shims: 1. 0.03 mm up to 1 mm 2. compliant with ROHS directive 3. EDM & ODM products |

| Application: |

Product details

|

Specification

|

|

|

Part Name:

|

|

|

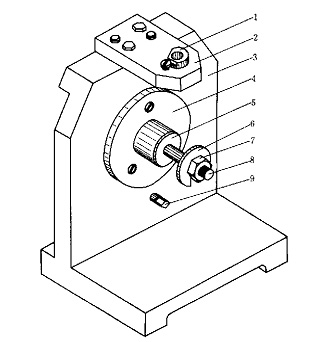

Application:

|

Used as parts of tool or machine

|

|

smallest hole

|

0.1mm

|

|

Volume / batch size

|

One to millions

|

|

surface

|

No burring, the surface is clean

|

|

Unit price:

|

Negotiate, price quoted based on material, thickness, tolerance and your quantity

|

|

Production capacity:

|

By using reel to reel etching,can achieve 1000 square meters per day

|

|

Lead time for mass production:

|

Usually 7 working days

|

|

Final inspection:

|

2D Gauge

|

|

Please note that the above figures for the stainless steel shim are given as a guideline. Should your stainless steel shim design fall outside these parameters please talk to one of our Technical Sales team who will be happy to talk through you requirement. Email:yw1@zldsmt.com

|

|

|

Why we use chemical etching to make your stainless steel shim?

|

|

|

1、Low cost for samples

|

|

|

2、Your company logo can be marked on the stainless steel shim

|

|

|

3、The highest precision can achieve +/-0.0075mm.

|

|

|

4、stainless steel shim with complex shapes can be etched, no additional cost

|

|

|

5、By chemical etching, Materialproperties , such as Magnetic properties, tensile strength will not be changed

|

|

|

6、material thickness ranging from 0.025 mm up to 1 mm parts can be used to make your stainless steel shim

|

|

|

7、Almost all metals can be etched, and there is no limit to your design

|

|

Part name:stainless steel shim

In-house R&D and production means lower prices!

We will make the stainless steel shim according to your CAD drawing (dxf or .dwg format will be better). We promise will not leak any information to the third part. It will be ok if you want us to sign a NDA file.

1. Our company is ISO14001:2004 and ISO9001:2008 certified. We consistently strive to produce superior-quality stainless steel shim. That’s why we use imported electrical-performance production machines and testing equipments from the US, France and Japan. And because of our huge production capacity and high quality standards,our output has been sourced by companies all over the world.

2. Price terms: FOB / EXW / CIF

3. Payment terms:

T/T, Paypal, western union, Escrow.

4.Packing method:

4.1 stainless steel shim will be individually packed and then bulk packed in agreed quantities. We will provide the best protection against damage caused during transit and under storage conditions.

4.2 Each package to visibly show the correct item code.

5. Quality management & Warranty

With over 12 years of technical experience, we are able to redesign and adjust both hardware and software to match your cost and application requirements. All the stainless steel shim we make for you are RoHS compliant.

All stainless steel shim dispatched will be previously checked according to predetermined quality checks. All quality testing comply with ISO9001:2008. Any items found to be defective prior to dispatch will be removed.

Should your stainless steel shim design fall outside these parameters please talk to one of our Technical Sales team who will be happy to talk through you requirement. Email: yw1@zldsmt.com

For more information of the stainless steel shim we can make for you, please visit our website below:

Related Products

Load...