- Scan to download[More]

Basic introduction to Cleanroom

A cleanroom is an environment, typically used in manufacturing or scientific research. It has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contamination that is specified by the number of particles per cubic meter at a specified particle size. To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5 μm and larger in diameter, corresponding to an ISO 9 cleanroom, while an ISO 1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3 μm and smaller.

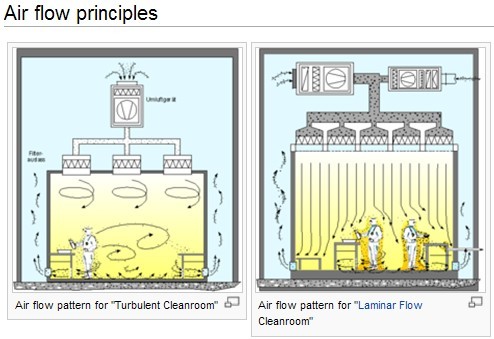

Air flow principles

The air entering a cleanroom from outside is filtered to exclude dust, and the air inside is constantly recirculated through high-efficiency particulate air (HEPA) and/or ultra-low penetration air (ULPA) filters to remove internally generated contaminants.

Staff enter and leave through airlocks (sometimes including an air shower stage), and wear protective clothing such as hoods, face masks, gloves, boots and coveralls.

Equipment inside the cleanroom is designed to generate minimal air contamination. Even specialised mops and buckets exist. Cleanroom furniture is also designed to produce a minimum of particles and to be easy to clean.

Common materials such as paper, pencils, and fabrics made from natural fibers are often excluded; however, alternatives are available. Cleanrooms are not sterile (i.e., free of uncontrolled microbes)[1] and more attention is given to airborne particles.

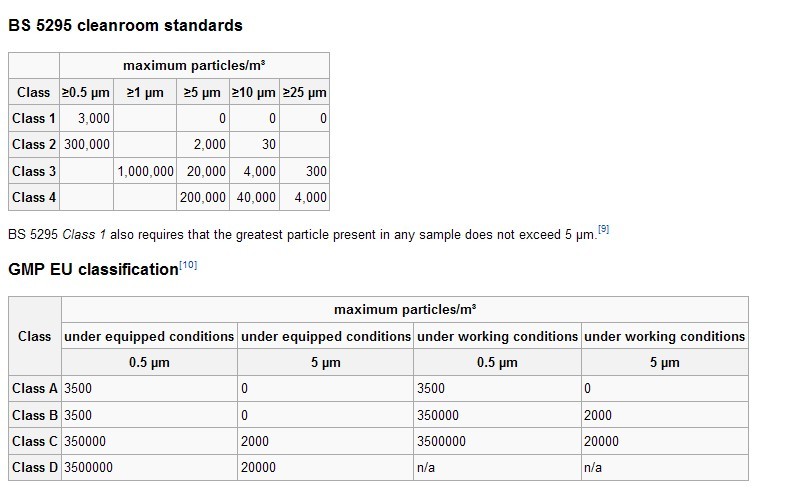

Cleanroom classifications

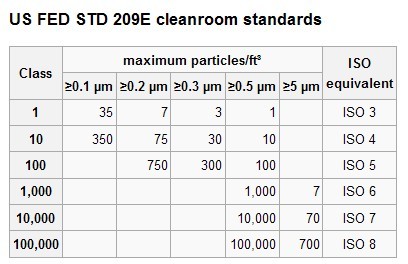

Cleanrooms are classified according to the number and size of particles permitted per volume of air. Large numbers like "class 100" or "class 1000" refer to FED-STD-209E, and denote the number of particles of size 0.5 µm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. "class 2000".

A discrete-particle-counting, light-scattering instrument is used to determine the concentration of airborne particles, equal to and larger than the specified sizes, at designated sampling locations.

Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 µm or larger permitted per cubic metre of air. So, for example, an ISO class 5 cleanroom has at most 105 = 100,000 particles per m³.

Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. For that reason, there is no such thing as zero particle concentration. The table locations without entries are non-applicable combinations of particle sizes and cleanliness classes, and should not be read as zero.

Because 1 m³ is approximately 35 ft³, the two standards are mostly equivalent when measuring 0.5 µm particles, although the testing standards differ. Ordinary room air is approximately class 1,000,000 or ISO 9.

Next:Packing roomPrevious:Imported etching machines

Information

- 2012-04-18Reel to reel Chemical Etching machine

- 2012-03-15chemical etching line

- 2012-03-15Exposure room

- 2011-12-28Checking equipment

- 2011-12-28Packing room

- 2011-12-28Clean room

- 2011-12-28Company prospects

- 2011-12-28Waste water treatment

- 2011-07-10Shenzhen Factory

- 2011-07-10Kunshan factory

Load...